Chain Drive |

|

|---|---|

|

Think back to an easier time, when the toughest challenge you faced as a pre-teen was getting

the chain back on your bicycle. If you did not mind getting your hands a little greasy, the

chain could be fixed in only one or two minutes, and you'd soon be peddling onward.

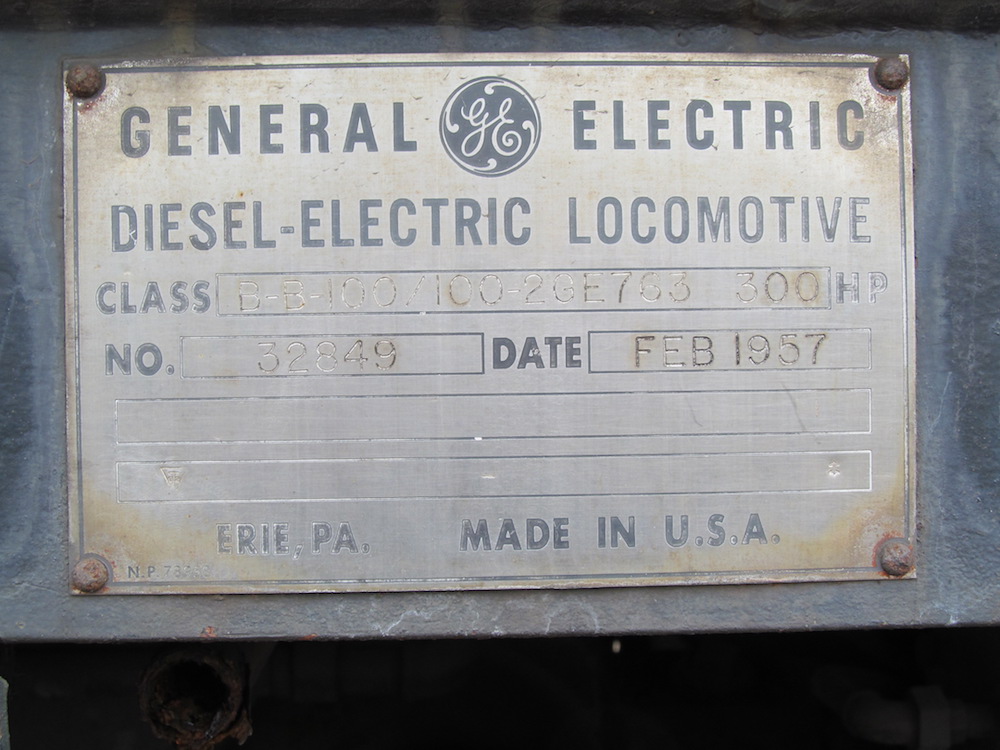

Let's contrast that scene to today and envision a shop mechanic (or museum volunteer for that matter) attempting to fix the heavy-duty chain which helps drive a 45 or 50-ton locomotive. On early GE 45/50 industrial switchers, the trailing axle on a truck was driven by a side-rod that connected to the front axle which was driven by a traction motor. GE eliminated the side-rods on later models in favor of a chain drive built within the truck to achieve the same result. A few photos from the underside of a so-called "critter" helps illustrate the complex nature of the work. The photos here depict the undercarriage commonly found on a General Electric 45/50-ton locomotive. In this case, its ex-Ohio Edison GE 50-tonner recently donated to the Beaver/ Lawrence Historical society located in West Pittsburg, Pennsylvania. Donated by the public utility company, the four-axle GE was built in February 1957 (s/n 32849). Volunteers have been busy restoring the pint-size locomotive to operating condition.

| |

Ohio Edison 50-Tonner arrives at Beaver / Lawrence site |

Gear reduction, drive sprocket and chain to outer axle of truck |

Gear reduction, sprocket and chain from inner axle to outer axle |

Reduction gear housing and traction motor |

Chain (end view) | |

Ohio Edison's Builder's Plate |

|